SILO

The SimQuest SILO project started in April

2003 and ran until October 2004. In this project the Nova College,

together with ROC A12, CORUS, CINOP, the University of

Twente, and publisher NijghVersluys developped 4 SimQuest

simulations for mechanical engineering. The simulations are not yet ready for publishing and they will be finnished in the near future by Simolution, a company that develops SimQuest simulations on a commercial basis. When complete, the simulations will be published

by NijghVersluys in the Tr@nsferW series.

The topics of the Dutch simulations are (click on the link to jump to the description on this page):

A fifth simulation, about aligning motor axes, was also developed. However, content in the form of assignments still has to be written and implemented here.

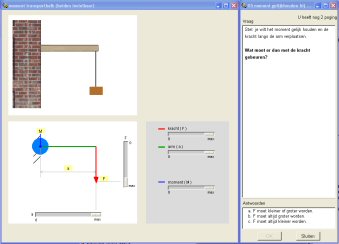

Momentenstelling 1 - basis

In this simulation the student encounters about the basic principles of moments. The formula Moment = Force · arm is introduced and various animations and interfaces are included to increase the learners insight into the subject of moments. The examples used in the simulation are a basic crane (a simple cantilever beam), a hoisting crane with contraweight and a wrench on a bolt. The simulation gradually builds from easy (a single weight on a fixed distance from a wall) to more difficult examples (two hands exerting forces on a wrench in different directions and on different distances from the bolt). Below you can find some screenshots (captures of a complete screen) of a few assignments with interfaces. Click on the images to enlarge (a new window will open).

Top

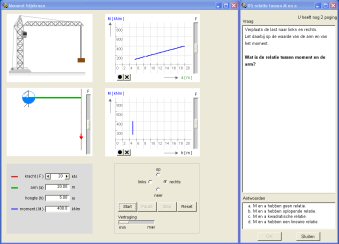

Momentenstelling 2 - evenwicht

This simulation is the continuation of momenten 1 - basis. Using this simulation, the student will discover that the sum of all moments about a point needs to be zero to maintain balance. Reactive forces (normal forces) are also introduced. The examples used are a simple balance, another hoisting crane, a wheelbarrow and finally a pressure valve security system.

Top

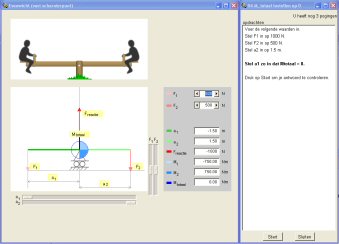

Buigen

In 'Buigen' the student learns about various aspects of bending plate materials. The influence of the bending radius, the thickness of the plate, the angle of bending and material specific constants on for instance the total length are explained. Also, shifting of the normal line or normal plane gets some attention. The simulation as it is features only one interface and animation with variable parameters. The other assignments in this simulation contain static images.

Top

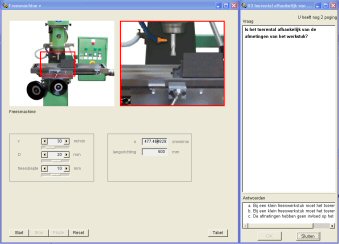

Snijsnelheden

Snijsnelheden is a simulation package about cutting speeds at a certain radial distance from the center of a rotating tool. Three different processes are used to explain the phenomenon of increasing cutting speed at a larger distance from the tool's center. These are: drilling, milling and 'turning'. The amount of rotations per minute and the radius of the tool are variables. The influence of linear speed (moving the piece of work linearly pass the tool) is also discussed.

Top

If you want to download any of the simulations above, go to the simulations pages. |